This article is reprinted. If there is any infringement, please contact us for deletion

Laser is one of the most widely used tools in today's manufacturing industry, especially with the development of additive manufacturing and Industry 4.0, engineers can create more complex features and product designs that require strict tolerances.

Laser processing can produce fine features that are difficult or impossible to manufacture with traditional processing equipment, and laser cutting is very clean, without producing burrs or thermal effects on surrounding materials, so there is no need for secondary precision machining. As medical equipment manufacturers design smaller and more advanced products, laser technology is becoming their preferred manufacturing technology.

Part 1

Laser marking

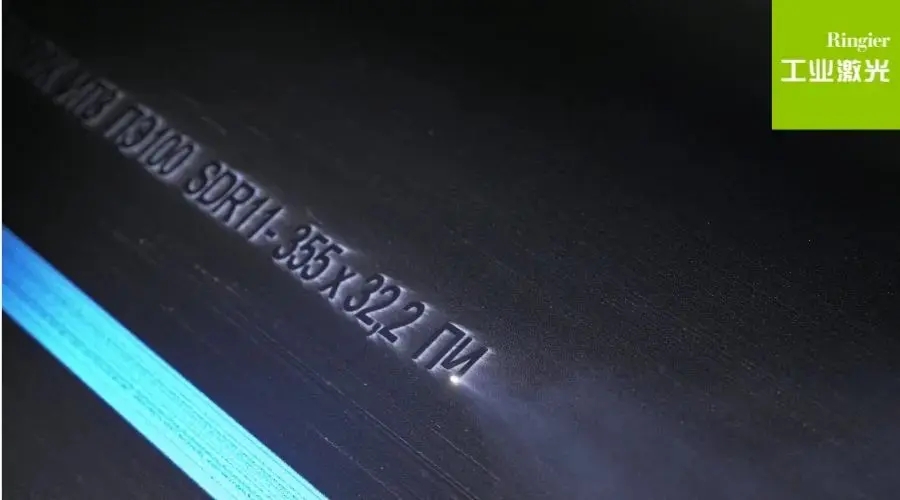

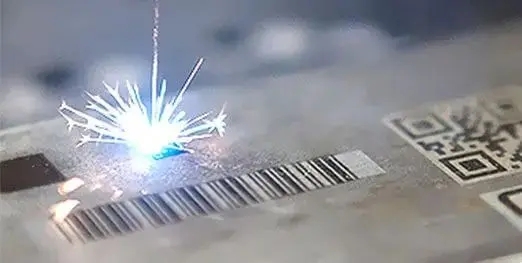

Laser is increasingly used to print unique identification (UID) numbers on components and products for easy tracking during recalls. For medical equipment, laser marking is very durable and can withstand multiple disinfections. The new type of marking includes readable information and barcode information, batch and batch codes, and even design history, which can be laser marked on products with geometric shapes of flat or curved parts.

From 2022 to 2027, the market size of laser marking equipment is expected to increase by $1.23 billion due to the growing demand for precise and permanent marking solutions in various industries. During the forecast period, the market's growth momentum will develop at a compound annual growth rate of 7.29%. Especially in emerging economies such as China and India, driven by the expanding healthcare and food and beverage industries, these industries require precise product coding during transportation.

Fiber laser marking, CO2 laser marking, UV laser marking, YAG laser marking, and diode laser marking are becoming increasingly prominent due to their versatility and efficiency. Laser engraving, laser etching, and laser coding are basic processes for various applications such as automobiles, aerospace, medical equipment, electronics, packaging, semiconductors, metals, plastics, glass, and wood.

The increasing demand for laser marking equipment in other end user industries is an emerging market trend. The increasing demand for laser marking equipment comes from different industries. Laser marking was originally used in graphic art and has now expanded to include greeting cards, advertising, party accessories, and stationery.

The emergence of laser marking in packaging, especially in food and cosmetics, has improved the appearance of products and enabled brands to stand out. As production capacity increases and costs decrease, this technology will flourish in precision processing factories, boosting demand for laser marking machines and promoting market growth.

Meanwhile, laser marking equipment manufacturers heavily rely on third-party suppliers for critical components, facing challenges such as quality issues, delivery delays, and strained relationships, which affect operational and cost efficiency.

Part 2

Surface texture

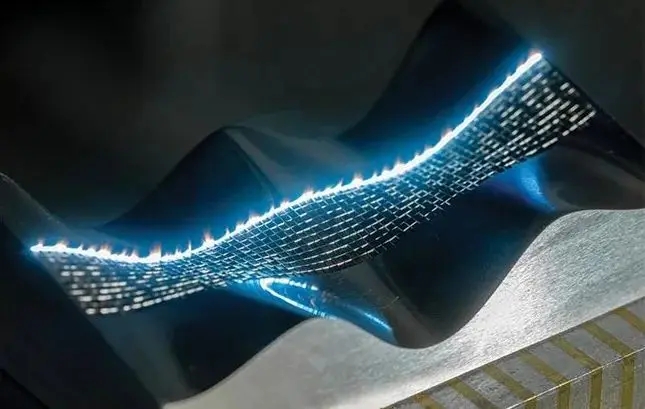

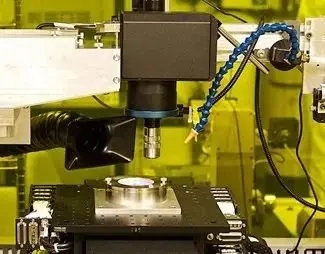

Laser can form textures or patterned microstructures on the surface of components or products, thereby improving physical properties such as wear rate, grip strength, optical performance, and load capacity. Laser microtexturing can create roughness on medical implants, making it easier for new tissues or bones to be fixed and grow into new implants, and can produce patterns with features as small as 10 micrometers at extremely high depth resolution..

Laser surface cleaning technology is no longer a novel technology, and it has been widely used in various industries. Similar to this technology are surface laser roughness or laser texturing. In laser surface treatment, the term texturing is more common because the light beam forms a certain ordered pattern. With the development of laser surface treatment technology, laser surface texture technology has also experienced rapid development. When using laser technology to texture the surface, roughness is achieved by removing material from the workpiece through the pulse action of the laser beam, resulting in pits and roughness.

For these purposes, using pulsed fiber lasers is the most suitable for this task. The use of laser technology for surface roughness also requires setting certain parameters to achieve varying degrees of roughness. The parameters that affect roughness include laser power, PRR (pulse repetition rate), scanner speed, and lens focal length.

By using laser technology, high-quality texture processing can also be performed on the surface of workpieces, and different degrees of roughness can be achieved by setting parameters. Customizable parameter sets provide many possibilities for achieving complete control of different roughness levels and processes. The main advantages of laser texturing include more precise processing, no need to mask other surfaces, repeatability of the process, no need for grinding media, the possibility of producing different textures in one step, and low operating and maintenance costs.

Part3

laser ablation

This "subtraction" processing method mainly utilizes a laser beam to accurately evaporate materials. The pulse length, wavelength, and intensity can be adjusted according to the processing material. This non-contact processing method is particularly useful for processing sensitive materials such as nanomaterials or superconducting materials, as it does not alter the material structure or damage the material surface due to wear or heating.

The increasing demand for miniaturized electronic components and the increasing use of laser technology in microelectronic manufacturing are driving the growth of the laser ablation system market. Meanwhile, advances in laser technology, such as developing ultrafast lasers and improving beam quality, are promoting more precise and efficient material removal processes.

The application of laser ablation systems in medical equipment manufacturing, semiconductor manufacturing, and nanotechnology research will be increasing, creating profitable opportunities for market participants. However, strict regulations regarding the use of safety and environmental issues related to the use of laser ablation systems pose challenges to market growth.

The market for laser ablation systems can be segmented based on technology, application, and end-users. According to technology, the market can be divided into nanosecond laser ablation, picosecond laser ablation, and femtosecond laser ablation. According to application, the market can be divided into microfabrication, surface cleaning, paint removal, etc. The end user industries of laser ablation systems include healthcare, electronics, automotive, aerospace, research laboratories, etc.

Part4

Laser drilling

The precision of laser drilling micrometer sized holes on various materials such as metals, polymers, and ceramics is incredible. Many manufactured products today require tiny features that can only be achieved through laser drilling. By using methods such as direct writing, perforation, and mask projection, very small and complex features can be created on various materials without generating thermal effects or damaging the materials.

Laser drilling is an extremely complex thermophysical process that involves the interaction between laser and material. Therefore, there are many factors that affect the quality of laser drilling. In order to obtain high-quality holes, it is necessary to analyze and understand the parameters that affect hole quality based on the general principles and characteristics of laser drilling. These parameters include laser pulse energy, pulse width, defocusing, pulse repetition rate, and the characteristics of the processed material.

Repeatability, accuracy, flexibility, and cost-effectiveness are the main reasons for the rapid popularization of laser drilling as a processing technology. For flat metal parts, the advantage of stamping is that it can form many holes, even different sizes, in one operation, which is conducive to forming multiple holes in parts in mass production.

Laser eliminates the need and cost of manufacturing stamping molds, providing low-cost solutions for prototypes or short-term parts. Laser drilling has no worn or broken components and can easily process high-strength materials. Unlike mechanical punching with a diameter limit of approximately 1.0-1.5 times the thickness of the sheet, laser has tremendous flexibility in any hole formation operation.

Part5

laser cutting

Similar to laser drilling, laser cutting relies on a focused laser beam to burn the material, straight cutting, or cutting pattern to a very precise depth within the material or component. Ultra fast lasers are commonly used for various types of metal and polymer processing because they can cut clean edges without creating a heat affected zone. Laser can cut various materials, including aluminum, titanium, and steel, with micrometer level tolerances.

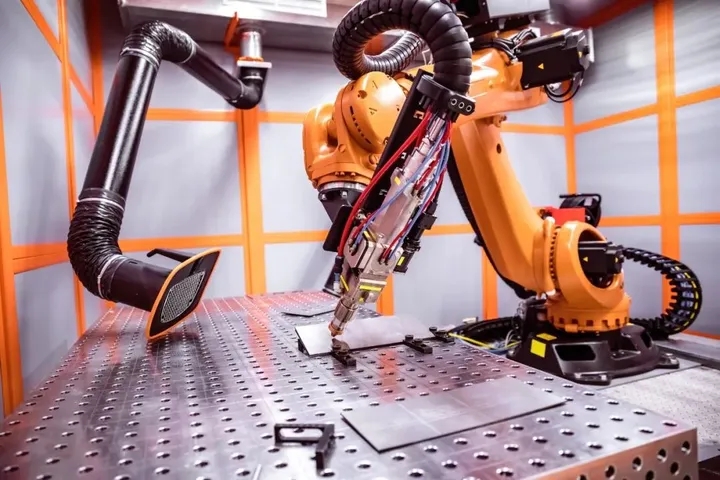

Robot laser cutting is a multi-directional and multi angle flexible cutting method achieved through industrial robots. The robot laser cutting system consists of a robotic arm, a material locator, a robot controller, and an end of arm tool (EOAT). Robots handle tools or workpieces to complete tasks.

According to the latest research from LPI (LP Information), robot laser cutting machines are expected to show stable growth in the future market. However, product differentiation, cost reduction, and supply chain optimization remain crucial for the widespread adoption of robotic laser cutting machines. Market participants need to invest in research and development, establish strategic partnerships, and adjust their products according to constantly changing consumer preferences to take advantage of the huge opportunities brought by the robot laser cutting machine market.

Part6

Laser welding

Welding processes are particularly effective for different materials with complex geometric shapes or difficult to connect together. According to different products, laser welding may be the best connection process compared to bonding or brazing, especially for connecting metals and plastics. It can also form sturdy and high-precision welding, providing repeatable quality.

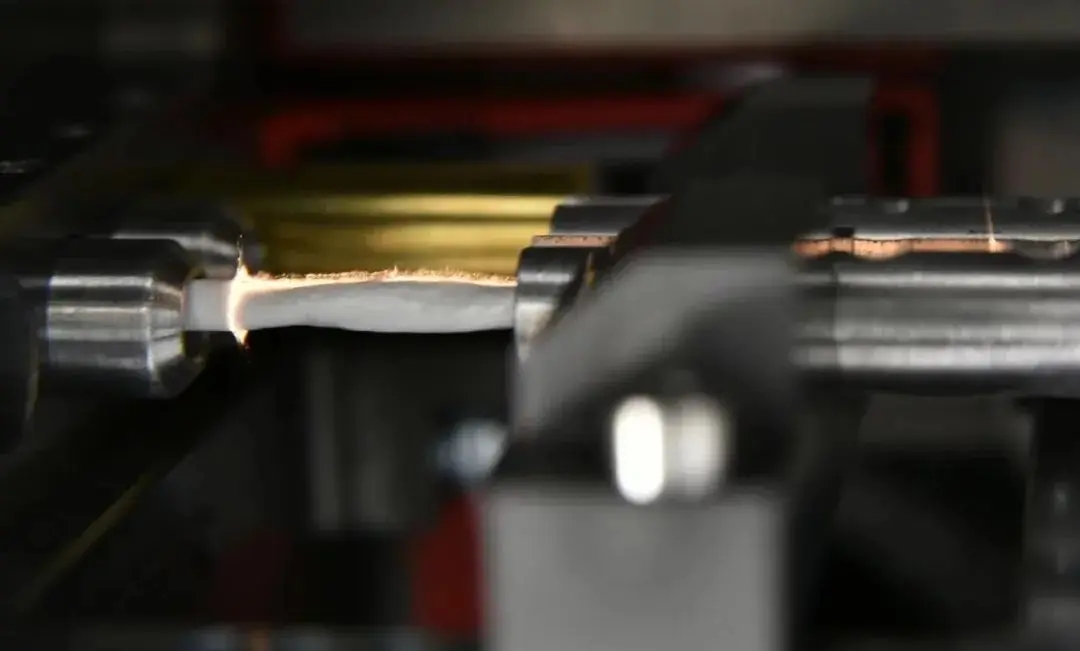

Laser welding is a melting welding process in which metals or thermoplastic materials are connected using a focused laser beam. This is an advanced welding process that has been applied in various industries, from aerospace, medical equipment to fine jewelry production. During the welding process, a highly concentrated beam of light is focused on the cavity between the materials to be joined. The powerful laser beam liquefies the edges of the material and fuses them to form a seam. Due to the use of this highly concentrated heat source, laser welding of thin materials can be carried out at high speed. In thicker materials, laser welding can produce deep and tight welds.

The advantages of laser welding include: the execution speed of the speed joint is much higher than traditional technology (about 4 times compared to TIG), and can reach 5000mm/min for certain applications; Non contact: heat is transmitted through a beam of light; High precision: Even in cases of significant thickness differences, energy can be concentrated in small areas to melt both sides of the joint. The total amount of transmitted energy is lower than that of TIG and MIG welding, reducing thermal deformation and the need for cooling components on the welding line.

In addition, laser welding is suitable for various materials. By adjusting the parameters of the laser, different materials, including copper and plastic, can be welded to form welding joints of different sizes and depths. The aesthetic effect of laser welding joints is comparable to that of professional TIG welding machines, but all operators can easily complete it and the execution speed is faster. If the application allows, the grinding stage after welding can be omitted without sacrificing the product's aesthetics.

Part 7

Stripping wire

Laser wire stripping is a fast process that provides excellent precision and process control while eliminating contact with wire, allowing for the processing of precision wire gauges larger than 32 AWG. The stripping error of the insulation layer can be controlled within 0.005 inches. Users can also program wire stripping to ablate the insulation layer at any point on the wire, achieving high-precision mid section stripping.

Nowadays, the use of lasers to remove insulation or coatings from wires, conduits, and other medical equipment has become the norm. There are many benefits to using laser exfoliation technology to manufacture medical devices, and the most important one is highly reproducible quality. Using a carbon dioxide laser to peel off the polymer insulation layer from the wire conductor, the laser energy is easily absorbed by the insulation layer but highly reflected by the metal conductor below. Due to the reflection of laser by the conductor, there is no risk of damage during the peeling process. Through laser peeling, there is no limit to the size of the wires that can be peeled off, and there is no risk of damaging the wires regardless of their size.

Laser wire stripping can strip circular, non circular, flat strip or any other shape of wire or cable. The stripping geometry includes end stripping, window stripping, longitudinal cutting, or full area ablation. This process is also very convenient for users. Compared to mechanical peeling methods, there is no need to replace blades or consumables. The process of laser wire stripping is non-contact, so it does not require frequent replacement and maintenance.

The medical device manufacturing market requires high-quality processes and increasingly complex and sophisticated wiring systems. Laser wire stripping can meet many challenges in the industry, and with the continuous development of smaller and more sophisticated medical equipment, laser wire stripping will continue to be the preferred method.