| Scheme overview

——————————————————————————————————————————————

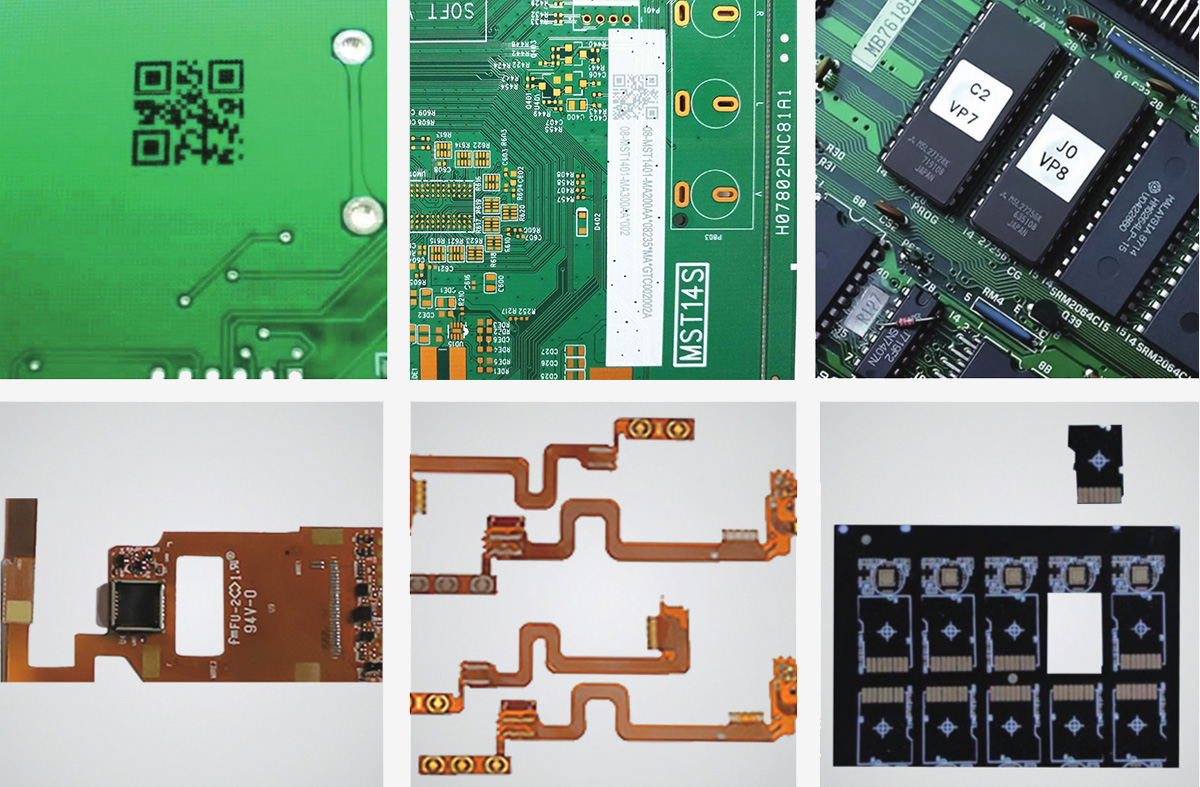

In the electronic and electrical industry, SMT Surface Mount Technology is a popular technology and process in the electronic assembly industry, which promotes the miniaturization and

multi-function of electronic products, and provides conditions for mass production and low defect rate production. At the same time, the wide application of SMT has also developed into

a huge industry in its own right.

The application of laser technology in the SMT industry is very wide, covering template cutting, welding, plate, marking, cutting, drilling, FPC cutting, covering film and other subdivisions.

For example, in SMT template manufacturing, laser processing replaces the original chemical etching method, precision metal parts laser forming, HDI(high density interconnect technology)

laser drilling, etc., it is because of the application of laser technology, so that it has made new breakthroughs in processing.

| Program advantage

——————————————————————————————————————————————

For products with complex precision and structure, as well as R & D samples with more design changes and fewer quantities, laser can be used for direct mass production, eliminating

the use of molds (mold production cycle is long and the cost is high).

a. High precision, position accuracy and dimensional accuracy are guaranteed, suitable for high-density design.

b, good quality consistency, low defect rate, suitable for large-scale, automated production needs.

c, fast speed, fewer production processes, simple operation, fast production speed, short delivery date.

d, no pollution, no chemical liquid in the production process, no pollution to the environment.

| Industry case

——————————————————————————————————————————————