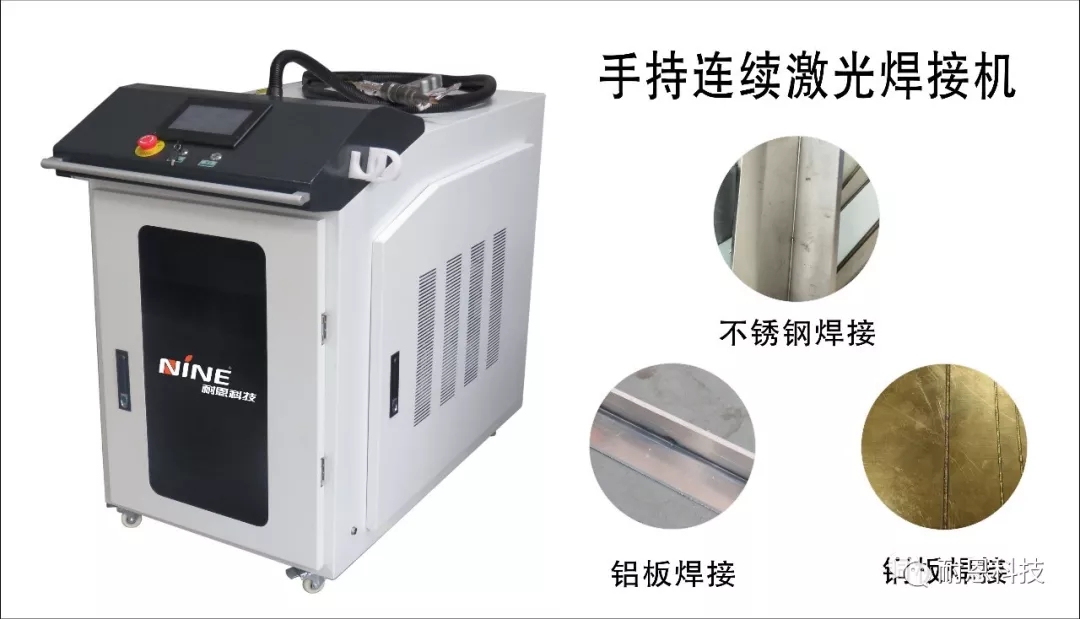

The hand-held laser welding machine can make the stainless steel kitchenware exquisite and beautiful. If you want to meet the aesthetic and personalized needs of customers for kitchenware,

the traditional welding method is difficult to complete the ideal role.

Kitchen utensils are used every day in our lives, such as stainless steel POTS and pans. But have you ever wondered how it's made? The kitchenware is made of a variety of raw materials,

some are the use of ceramics, some plastic, some metal stainless steel. Today we are talking about metal stainless steel raw materials, we know that one of the processes in the production of kitchen

utensils is welding.

Kitchenware laser welding machine saves energy about 80%~90%. Compared with arc welding, the processing cost can be reduced by about 30%. Can weld dissimilar steel and dissimilar metal, simple completion of mechanization and automation.

Fast speed, small deformation, small heat affected zone, with high and depth-width ratio.

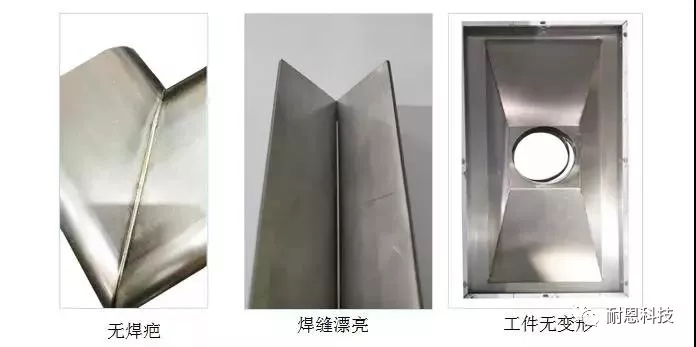

The weld is beautiful, smooth, no porosity, no treatment or simple treatment after welding.

Small focus point, no pollution, high precision positioning.

The hand-held laser welding machine can perform small open parts and precision welding.

Kitchenware because laser welding heat input is very low, the amount of deformation after welding is very small, and can get a very beautiful welding surface effect, welding follow-up treatment is very little, handheld stainless steel laser welding machine can greatly reduce or eliminate the huge polishing and leveling process on the labor cost.